Multistack Chiller Helps Georgia Hospital Improve

Comfort and Save Significant Energy Costs

Marietta, Georgia

New Chiller Helps Windy Hill Hospital save $60,000 in only seven months

Challenge

In late 2009 Windy Hill Hospital, Marietta, Georgia, selected the Padgett Group as their HVAC services provider. The Padgett Group was retained to not only operate and maintain the HVAC systems, but also develop long term strategies for replacing the hospital’s 20 year-old chillers that had been installed in the early 1990s. These included two 200 ton air-cooled chillers for one building, and two 100 ton water-cooled chillers serving the other building. The two buildings operated independently of each other.

Solution

Tony Padgett, Chairman of The Padgett Group, said, “Shortly after being selected as the hospital’s HVAC service provider, we suggested that the two buildings be connected with common piping and pumps to provide improved redundancy and the most efficient means of cooling.”

“Soon after making those recommendations and their being approved, the two 20 year-old100-ton water-cooled chillers experienced major component failures.”

The Padgett Group analyzed the cost of repairs to the chillers and then calculated the potential cost savings that could be achieved by replacing two of the chillers with a single 300 ton Multistack chiller to handle the cooling for both buildings.

Padgett says, “This scenario would take offline a minimum of one 200 ton air-cooled chiller and both 100 ton water-cooled chillers. After looking at the investment needed in repairing two 20 year-old chillers and the calculated savings available by installing a Multistack chiller, Mr. Danny Dunn, Chief Engineer at Windy Hill Hospital, decided to move forward with the installation of a new Multistack chiller. Mr. Dunn was an integral part of the project, from inception to completion and monitoring the energy savings.”

Results

During the equipment room renovation, the two smaller water-cooled chillers continued to serve the two buildings separately, one with the air-cooled chillers and the other with a rental air-cooled chiller.

About WellStar Health System:

- Five hospitals

- Five urgent care centers

- 14 satellite diagnostic imaging centers

- One adult congregate living facility

- One skilled nursing facility

- One inpatient hospice

- More than 500 primary care providers, specialists and advanced practitioners known collectively as the WellStar Medical Group

- More than 100 WellStar Medical Group practice locations

- More than 12,000 employees

- 1,126 Medical Staff members

The Padgett Group decided to install a single 300 ton water-cooled, flooded evaporator Multistack chiller to replace the two smaller 100 ton water-cooled chillers. Tony Padgett said, “Our reasoning for installing the 300 ton Multistack chiller was based on what we believed the combined actual load of the two buildings to be, also considering the buildings’ physical and electrical limitations.”

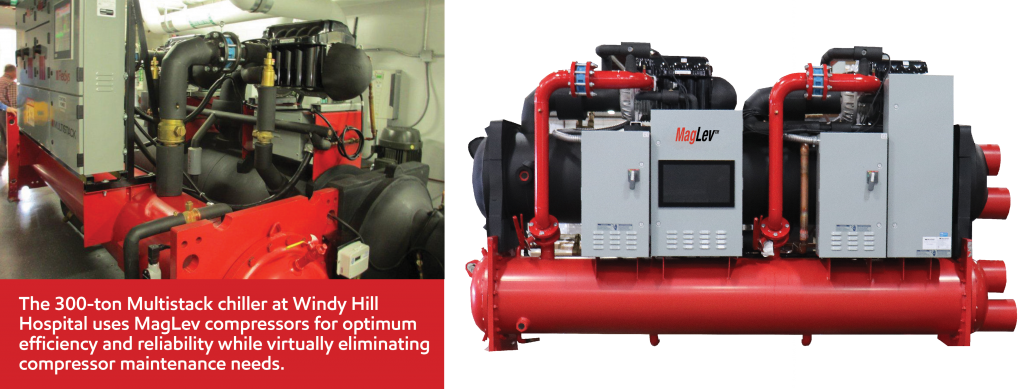

Multistack flooded evaporator chillers include the innovative, energy saving MagLev compressors. With its oil-free design and multiple compressors, the Multistack chiller efficiently satisfies cooling load by operating only enough compressors necessary. Efficiency is further boosted with the magnetic levitation technology, eliminating old technology mechanical bearings and lubricating oil systems. Each MagLev compressor includes an integral variable speed drive. Windy Hill also left in place the air-cooled chillers and integrated them into the piping scheme to provide additional emergency backup.

Another advantage of the Multistack chiller is its small footprint. The chiller was shipped knocked down for easier equipment room entry through a single width door and then reassembled once inside the room. Padgett adds, “Due to the Multistack chiller’s low sound levels we were able to reuse the existing space that is in a hallway in the interior of the facility. These advantages helped Windy Hill negate the perceived need to build a standalone building to house a typical centrifugal chiller, another huge savings to the owner.

“Our energy savings projections were based on several factors— some known and some unknown. We ‘assumed’ the combined cooling load of the buildings to be a minimum of 300 tons on design days and somewhat less at other times. We had no original design information to go by. We have found, however, that the combined load is not as large as the hospital thought it was. We have not seen more than 250 tons to date.”

As a result of replacing the older chillers with a new, more reliable and more efficient single Multistack chiller, the hospital’s electrical consumption and peak demand charges have been significantly reduced. Additional savings have resulted due to reduced service and repair needs since removing the old chillers. With the new Multistack chiller, repairs are “zero” and service costs are down, as well.

Says Padgett, “Our savings have not only reduced kWh consumption, but have made a sizeable reduction in the peak demand of the facility. Our savings have impacted the facility with 19.8 percent overall reductions in kWh usage for the entire facility and a 22.6 percent reduction in demand billing. “These numbers equate to a $60,000.00 savings over the seven month performance period from May to November, 2011— verified by MarionEco, an independent, third-party sustainability company.”

Padgett notes that the cost savings are derived while paying only $0.052/kWh winter and $0.058/kWh summer rates plus the demand charges. The dollar savings will increase over the same time period next year as greater billing demand savings come into effect. Danny Dunn, Windy Hill Chief Engineer, said of the project and Multistack chiller, “This project has met all expectations including reduced energy costs as well as chiller performance. This was a great decision for the Windy Hill Hospital. “

About the Padgett Group

Padgett Group focuses on improving facilities environments while reducing owning and operating costs. Padgett Group has a rich 20 year history working with facilities in the Southeast United States to help increase productivity, reduce owning and operating costs, boost profitability and demonstrate measurable improvement in overall facilities performance. Padgett Group is a leader in design build construction, facilities management, energy management and consulting services. They are a founding member of SPGroup, a nationwide group of industry leading companies providing facility services to building owners. Padgett Group is also a U.S. EPA ENERGY STAR partner focusing on environmental stewardship and energy conservation.

About Windy Hill Hospital

WellStar Health System’s Windy Hill Hospital is an acute long-term care hospital in Marietta, Georgia, with 115 beds. The hospital opened in 1973 and is home to the South east’s largest Sleep Disorders Center plus nationally recognized specialties in long-term acute care, interventional radiology and outpatient rehabilitation. Windy Hill includes an 18,900 square foot Outpatient Surgery Center; and pharmacy. A Long Term Acute Care (LTAC) unit serves patients with an acute illness and who need an extended hospital stay. Windy Hill is accredited by JCAHO and recognized by the Institute for Healthcare Improvement for reducing healthcare associated infections. Windy Hill Hospital’s parent company, WellStar Health System has been recognized by AARP as one of the nation’s Best Employers for Workers Over 50, and in 2010 received Top Ten honors in Working Mother magazine’s annual 100 Best Companies for Working Mothers program.